Industrial Applications

with the QUEEN 1.

Print XXXL parts yourself in the enterprise.

The QUEEN 1 prints everything from plant and mechanical engineering to the automotive sector for commercial vehicles and agricultural machinery to ergonomic and medical technology products.

Parts & Service

Innovation for XXXL 3D Parts

The QUEEN 1 is the manufacturing tool tailored to your professional needs for extra-large and functional parts without trade-offs in resolution or print duration.

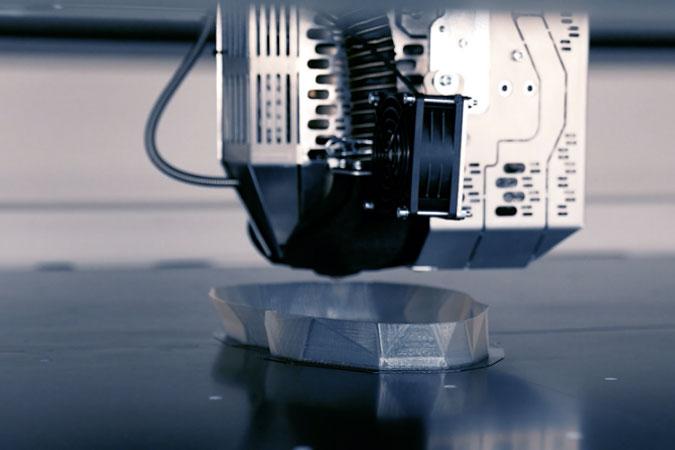

VFGF Print Head

The print head with variable nozzle diameter allows to print fine surfaces and still be up to 40 times faster compared to 3D printing with filament.

SOLUTIONS

Granulate

Using plastic granulates makes large-format 3D printing economical and allows materials with serial properties to be used.

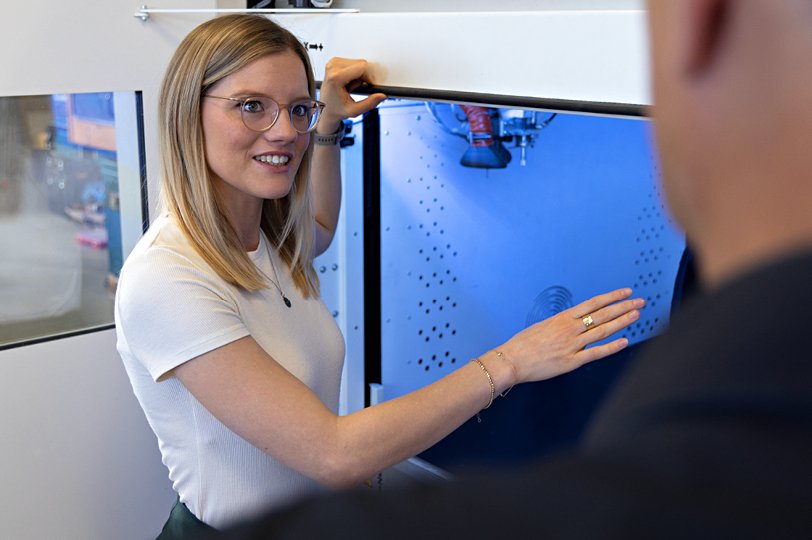

SOLUTIONSWe advise you completely

according to your requirements.

Let’s talk.

Katja Herrmann

Founder / CEO

Tel. +49 7361 806 49 00

Oliver Friz

CEO / Sales

Tel. +49 7361 806 41 02

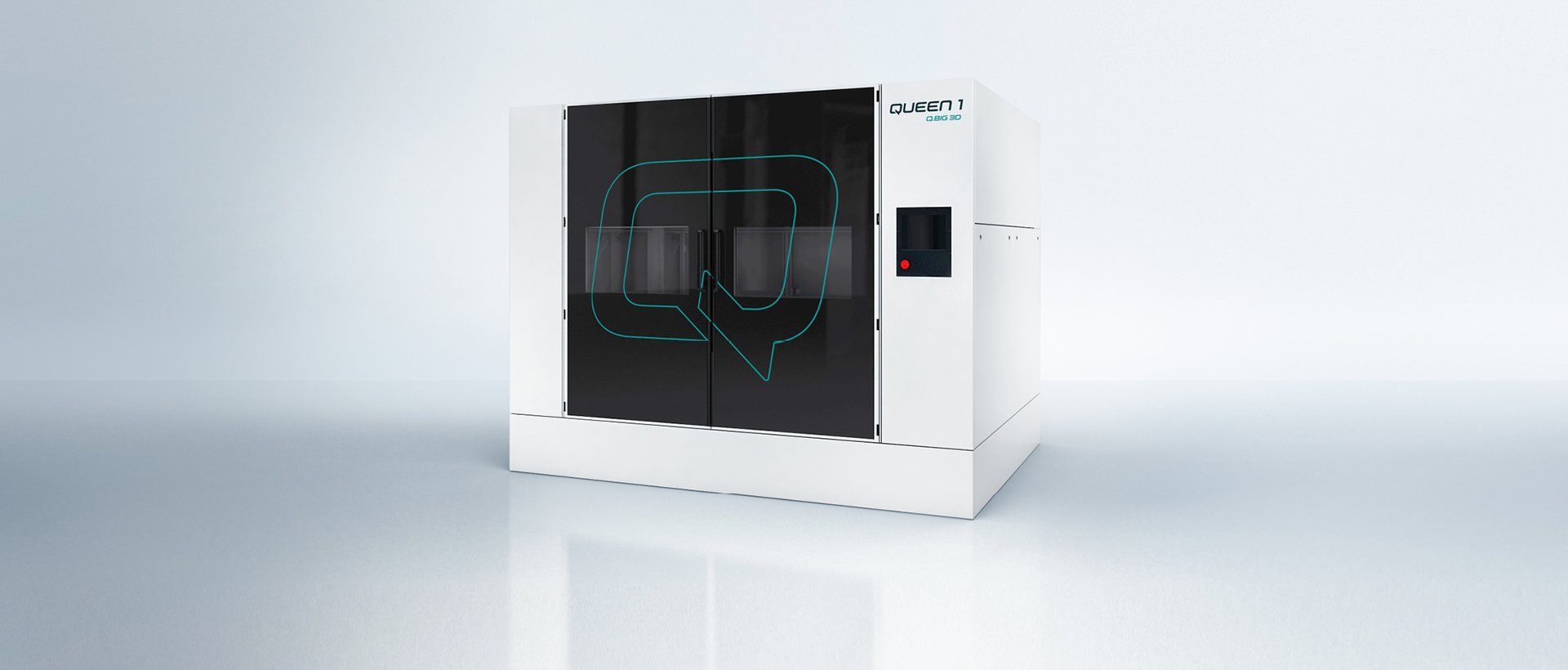

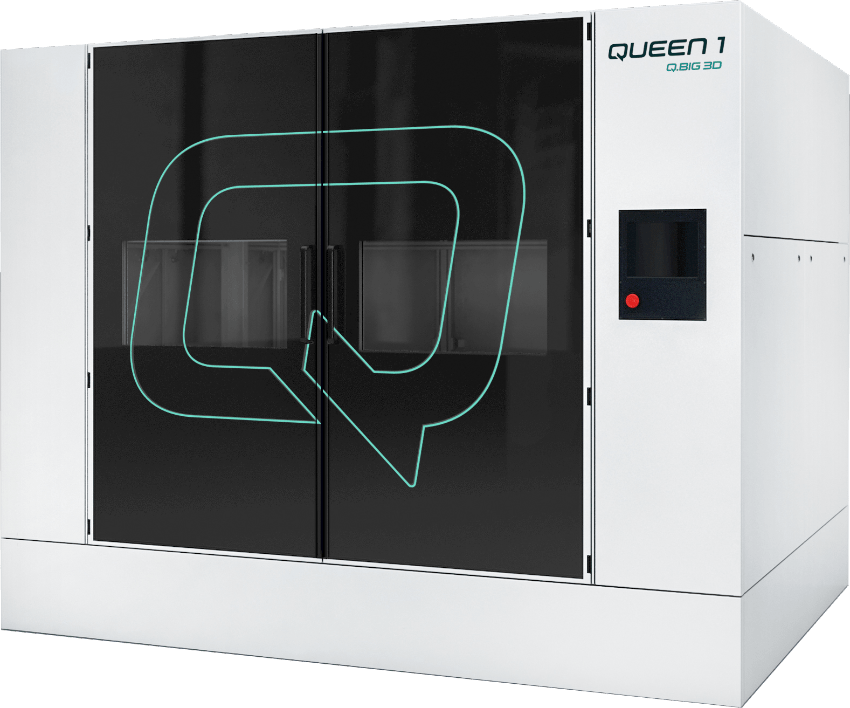

The XXXL 3D Printer:

QUEEN 1.

The innovation for additively manufactured components

Facts & Figures

OUTER DIMENSIONS & BUILT SIZE

Outer dimensions

W 2980 mm / H 2535 mm / D 2210 mm

Built size

W 1700 mm / H 1050 mm / D 1050 mm

Kinematics

Linear axes with ball screws

VFGF-speed

max. 500 mm/s

Print bed temperature

max. 120 °C

Built chamber temperature

max. 80 °C

PRINT HEAD

Variable Nozzle

1.5 mm (Detail) to 3 mm (Turbo)

Dynamic output

0.15 – 2.0 kg/h

Resolution layer height

0.3 mm (Detail) to 1.2 mm (Turbo)

Nozzle temperature

max. 350°

Process

VFGF (customised process algorithms)

GRANULATE

Granulate grain size

Standard

Material

Plastics

– PLA

– Precision polyamide 6 (25% Fiberglass)

QUEEN 1.

Spec Sheet